Website Design Copyright 2025 © 竹新化學股份有限公司 & 頂烽企業股份有限公司

All Rights Reserved. 網頁設計 by 覺醒設計

Our company boasts state-of-the-art factory facilities that enable us to maintain high standards of production and deliver top-quality products to our customers.

Our commitment to innovation and efficiency is reflected in our advanced equipment and well-designed production processes.

Here is an overview of our key factory facilities:

Our company's inventory area boasts an impressive storage capacity of 60,000 metric tons. This is of paramount importance to our production of calcium carbonate powder. It means that we can store a substantial amount of raw materials, ensuring uninterrupted production and timely fulfillment of customer demands. Whether it's bulk production or adapting to market fluctuations, we have an ample inventory capacity to guarantee a stable and reliable supply for you.

APEX

The crushing station is responsible for breaking down large raw materials into smaller particles. The washing station is used to clean and purify materials that have already been processed by the crushing station. It removes impurities such as clay, sand, or other contaminants from the raw materials. This purification process ensures that the final calcium carbonate powder has the highest level of purity, ensuring the integrity and purity of our calcium carbonate powder, and meeting the strict requirements of various industrial applications. Our calcium carbonate powder is renowned for providing excellent performance and versatility in different industries, and the operation of these stations ensures that our products consistently maintain the highest quality standards.

APEX

The raw materials used by Apex, such as dolomite and limestone, are the primary ingredients in the production of calcium carbonate powder. Hoppers play a crucial role by not only storing an adequate quantity of raw materials but also precisely controlling their supply speed and quantity. This precision ensures that every batch of powder maintains consistent composition and quality, which is essential for our product quality. Additionally, APEX has automated the raw material supply, reducing labor requirements and significantly improving production efficiency. This automation technology helps save costs while ensuring our products consist only of the highest quality raw materials. Lastly, our Hoppers are designed with excellent dust control features, minimizing dust generation and leakage. This promotes a clean working environment and the health of our employees.

APEX

The Vertical Milling Machine is used in the production process of calcium carbonate powder. It has the capability to transform raw materials from block or granular forms into the desired fine powder, ensuring a uniform particle size distribution. The high precision and adjustability of the Vertical Milling Machine allow it to meet various requirements for powder particle sizes. Furthermore, the Vertical Milling Machine enables continuous processing, reducing production time and costs while ensuring high-quality and efficient powder production. By providing high-precision machining, it facilitates the versatility and widespread application of calcium carbonate powder, thus promoting the development and innovation of calcium carbonate industries.

APEX

Apex employs twin-screw extruders in the production of Masterbatch, a practice of utmost importance in the plastics industry. These twin-screw extruders are celebrated for their exceptional mixing capabilities and high efficiency, which in turn ensures the uniform and efficient manufacturing of Masterbatch. Their versatility is evident in their ability to process various plastic and rubber materials, meeting the diverse requirements of different industries, whether for coloring, enhancing functionality, or addressing specific needs. Apex's Masterbatch is highly esteemed among customers for its multifunctionality, precision, and dependability.

MASTERBATCH INTRO

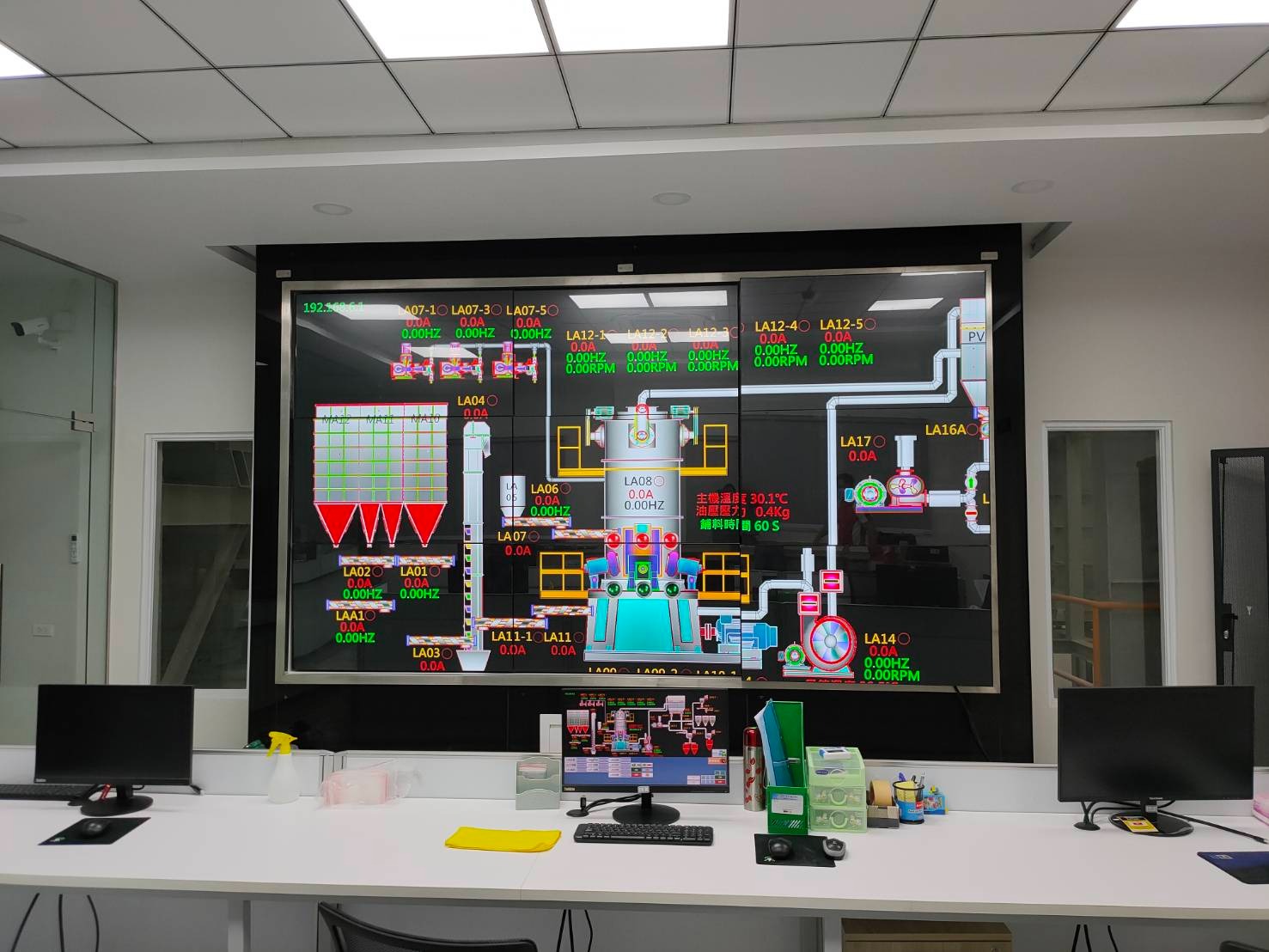

Human Machine Interface (HMI) is crucial in calcium carbonate production lines. It enables real-time monitoring of production processes, enhancing efficiency and ensuring high-quality products. HMI swiftly detects faults, reducing production interruptions. It records vital data for quality control, performance evaluation, and improvement guidance. HMI is user-friendly, requiring no deep technical knowledge, thus simplifying operations. Some systems support remote monitoring and operation, increasing flexibility. In summary, HMI application contributes to efficient production, excellent quality control, and troubleshooting, which are paramount for calcium carbonate products.

APEX

The semi-automatic filling and packaging area are crucial in calcium carbonate powder production. It combines the flexibility of human labor with the efficiency of machinery, ensuring our products meet the highest packaging standards. This enhances packaging speed and consistency, reduces the risk of errors, improves workplace safety, and strengthens production traceability, ensuring customers receive high-quality products on time.

APEX

Robotic Stacking Systems offer the capability to stack products at an exceptionally fast pace and with remarkable consistency, far outperforming traditional manual stacking methods. This translates to the ability to process a greater number of products in a shorter time frame during the packaging phase. Consequently, it reduces dependence on labor, lowers labor costs, enhances production efficiency, and ensures that each package shares identical appearances and quality. This latter aspect is of paramount importance to APEX in maintaining the consistency and quality control of calcium carbonate products.

APEX

Our dedicated quality control and testing labs are equipped with modern testing equipment and instruments to perform rigorous quality checks at various stages of production. We conduct thorough analyses to ensure that our products meet or exceed industry standards. Lab introduction click below button

Lab introduction

Our robust and reliable finished goods inventory can accommodate 30,000 tons of inorganic powder, 10,000 tons of modified powder, and 10,000 tons of functional pellets each month. This critical facility represents our commitment to exceptional quality. Whether you're in construction, plastics, paints, paper, or other industries, we can provide you with the right quantity of high-quality materials to ensure the smooth operation of your production. At Apex, our quality control is stringent, and our products meet industry standards. We take pride in our stability and reliability, delivering impeccable materials to you.

APEX

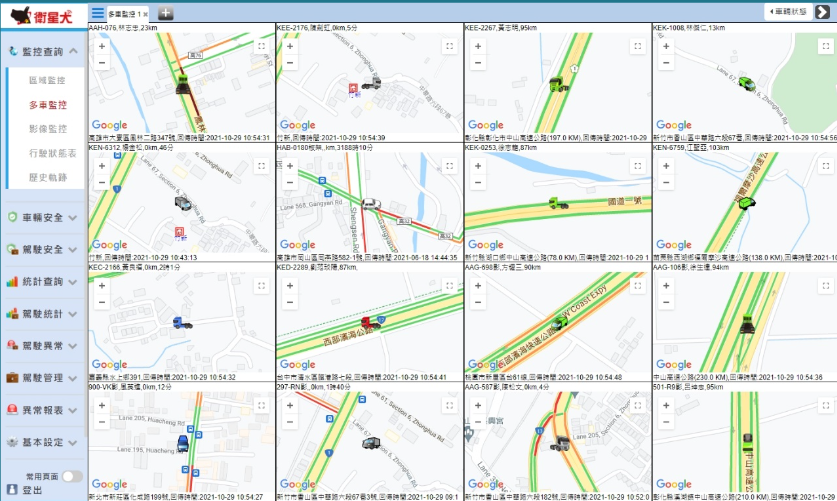

APEX takes pride in its in-house fleet of vehicles. We have a range of specialized transport options including powder tankers, 20-foot tilting container trucks, 40-foot flatbed trucks, 35-foot flatbed trucks, 41 and 36-foot curtain-sided trucks, 17-ton lorries, and 11-ton lorries to cater to various cargo transport needs. Our fleet is meticulously maintained, operated by experienced drivers, ensuring safe and reliable cargo delivery. Whether your logistics needs are big or small, we offer top-notch transportation solutions.

APEX

Our corporate fleet is equipped with a real-time satellite GPS monitoring system, enhancing fleet management and providing customers with estimated arrival times.

APEX

We use cookies to collect and analyze information on site performance and usage. By Clicking "Continue" or by clicking into any content on this site, you agree to allow cookies to be placed. To find out more, please visit our privacy policy。

CONTINUE GO TOP

GO TOP